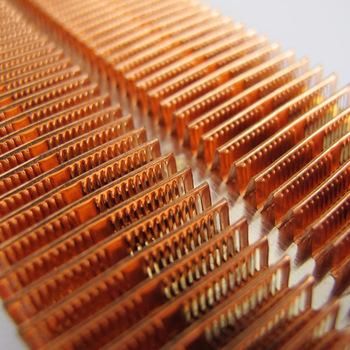

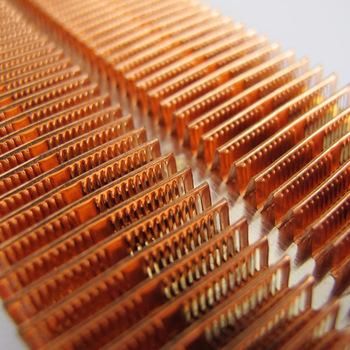

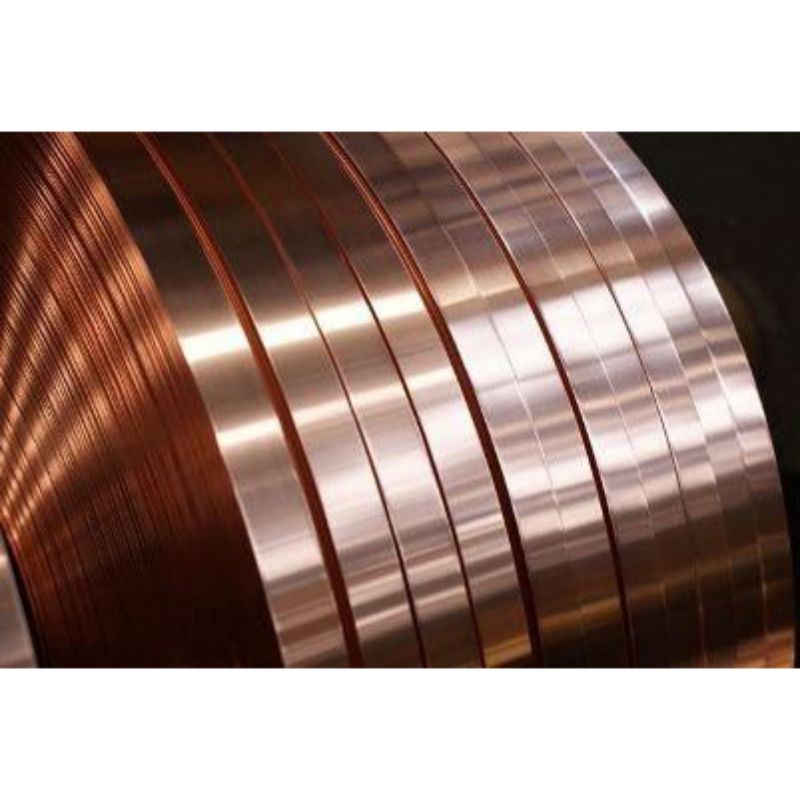

C14415 tooj liab ntawv ci sawb, tseem hu ua CuSn0.15, yog ib hom ntawm tooj liab alloy sawb siv nyob rau hauv ntau yam kev siv. Qhov zoo ntawm C14415 tooj liab sawb ua rau nws muaj ntau yam khoom siv rau ntau yam khoom siv hluav taws xob thiab khoom siv hluav taws xob uas xav tau kev ua haujlwm siab, kev ua haujlwm zoo, thermal conductivity, lub zog, thiab corrosion kuj.

Tshuaj muaj pes tsawg leeg

| UNS: C14415

(JIS: C1441 EN: CuSn0.15) | Cu+Ag+Sn | Sn |

| 99,95 nqi. | 0.10–0.15 dr hab |

Mechanical Properties

| Kub | Tensile zog

Rm

MPa (N / hli 2) | Hardness

(HV 1) |

| GB | ASTM | JIS |

| H06 (Ultrahard) | H04 | H | 350-420 Nws | 100-130 |

| H08 (Elasticity) | H06 | EH | 380-480 Nws | 110-140 ib |

| Lus Cim: Cov ntaub ntawv kev kawm hauv cov lus no raug pom zoo. Cov khoom lag luam nrog lwm cov khoom tuaj yeem muab tau raws li cov neeg siv khoom xav tau. 1) tsuas yog rau kev siv. |

Lub cev muaj zog

| Qhov ceev, g / cm3 | 8.93 ib |

| Hluav taws xob conductivity (20 ℃), % IACS | 88 (ntxiv) |

| Thermal conductivity (20 ℃), W / (m·℃) | 350 |

| Coefficient ntawm thermal expansion (20-300 ℃), 10-6 / ℃ | 18 |

| Lub peev xwm tshwj xeeb kub (20 ℃), J / (g· ℃) | 0.385 ib |

Thickness thiab Dav Tolerances mm

| Thickness kam rau ua | Dav Tolerance |

| Thickness | Ua siab ntev | Dav | Ua siab ntev |

| 0.03-0.05 Nws | ± 0.003 | 12-200 Nws | ± 0.08 hli |

| > 0.05 ~ 0.10 | ± 0.005 |

| > 0.10 ~ 0.18 | ± 0.008 |

| Lus Cim: Tom qab kev sib tham, cov khoom lag luam nrog cov kev xav tau siab dua tuaj yeem muab tau. |