tooj liab ntawv ciyog ib yam khoom tsim nyog nyob rau hauv Circuit Court board manufacturing vim hais tias nws muaj ntau lub zog xws li kev sib txuas, conductivity, tshav kub dissipation, thiab electromagnetic shielding. Nws qhov tseem ceeb yog qhov tseeb ntawm nws tus kheej. Hnub no kuv yuav piav qhia rau nej txogdov tooj liab ntawv ci(RA) thiab Qhov txawv ntawmelectrolytic tooj liab ntawv ci(ED) thiab kev faib tawm ntawm PCB tooj liab ntawv ci.

PCB tooj liab ntawv ciyog cov khoom siv hluav taws xob siv los txuas cov khoom siv hluav taws xob ntawm cov khoom siv hluav taws xob. Raws li cov txheej txheem tsim khoom thiab kev ua haujlwm, PCB tooj liab ntawv ci tuaj yeem muab faib ua ob pawg: dov tooj liab (RA) thiab electrolytic tooj liab ntawv ci (ED).

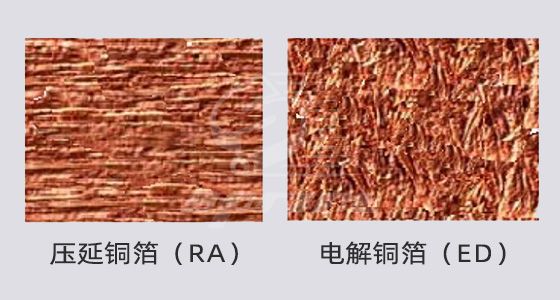

Rolled tooj liab ntawv ci yog ua los ntawm cov ntshiab tooj liab blanks los ntawm kev nruam dov thiab compression. Nws muaj ib tug du nto, tsis tshua muaj roughness thiab zoo hluav taws xob conductivity, thiab yog haum rau high-frequency teeb liab kis tau tus mob. Txawm li cas los xij, tus nqi ntawm cov ntawv yob tooj liab yog siab dua thiab cov tuab tuab yog txwv, feem ntau ntawm 9-105 µm.

Electrolytic tooj liab ntawv ci yog tau los ntawm electrolytic deposition processing ntawm ib phaj tooj liab. Ib sab yog du thiab ib sab yog ntxhib. Lub sab ntxhib yog sib txuas rau lub substrate, thaum lub sab du yog siv rau electroplating los yog etching. Qhov zoo ntawm electrolytic tooj liab ntawv ci yog nws cov nqi qis dua thiab ntau yam thicknesses, feem ntau ntawm 5-400 µm. Txawm li cas los xij, nws qhov roughness saum npoo yog siab thiab nws cov hluav taws xob conductivity tsis zoo, ua rau nws tsis tsim nyog rau kev xa xov hluav taws xob ntau zaus.

Kev faib tawm ntawm PCB tooj liab ntawv ci

Tsis tas li ntawd, raws li qhov roughness ntawm electrolytic tooj liab ntawv ci, nws tuaj yeem muab faib ua ntau hom hauv qab no:

HTE(High Temperature Elongation): High-temperature elongation copper foil, feem ntau yog siv nyob rau hauv multi-layer circuit boards, muaj zoo kub kub ductility thiab bonding zog, thiab roughness feem ntau yog nyob nruab nrab ntawm 4-8 µm.

RTF(Reverse Treat Foil): Rov qab kho cov ntawv ci tooj liab, los ntawm kev ntxiv cov txheej txheej tshwj xeeb ntawm cov ntawv ci electrolytic tooj liab los txhim kho cov nplaum ua haujlwm thiab txo qhov roughness. Qhov roughness feem ntau yog nyob nruab nrab ntawm 2-4 µm.

ULP(Ultra Low Profile): Ultra-low profile tooj liab ntawv ci, tsim siv cov txheej txheem electrolytic tshwj xeeb, muaj qhov tsis tshua muaj qhov ntxhib thiab tsim nyog rau kev sib kis ceev ceev. Qhov roughness feem ntau yog nyob nruab nrab ntawm 1-2 µm.

HVLP(High Velocity Low Profile): High-speed low-profile tooj liab ntawv ci. Raws li ULP, nws yog tsim los ntawm kev ua kom cov electrolysis ceev. Nws muaj qhov roughness qis dua thiab ua haujlwm ntau dua. Qhov roughness feem ntau yog nyob nruab nrab ntawm 0.5-1 µm. .

Post lub sij hawm: May-24-2024