Tinned tooj liab stripyog cov khoom siv hlau nrog ib txheej ntawm tin rau ntawm qhov chaw ntawm tooj liab. Cov txheej txheem ntawm tinned tooj liab sawb tau muab faib ua peb kauj ruam: kev kho ua ntej, tin plating thiab tom qab kho.

Raws li txoj kev sib txawv tin plating, nws tuaj yeem muab faib ua electroplating thiab kub-dip plating. Muaj qhov sib txawv ntawm electroplated tinned tooj liab sawb thiab kub-diptinned tooj liab stripnyob rau hauv ntau yam.

I. Txheej txheem txheej txheem

1) Electroplating tinning: Nws siv lub hauv paus ntsiab lus ntawm electrolysis siv lubtooj liabraws li lub cathode thiab tin raws li lub anode. Nyob rau hauv cov tshuaj electroplating uas muaj tin ions, cov tin ions raug txo thiab tso rau ntawm qhov chaw ntawm cov tooj liab los ua ib txheej tin-plated los ntawm qhov kev txiav txim ntawm cov tam sim no.

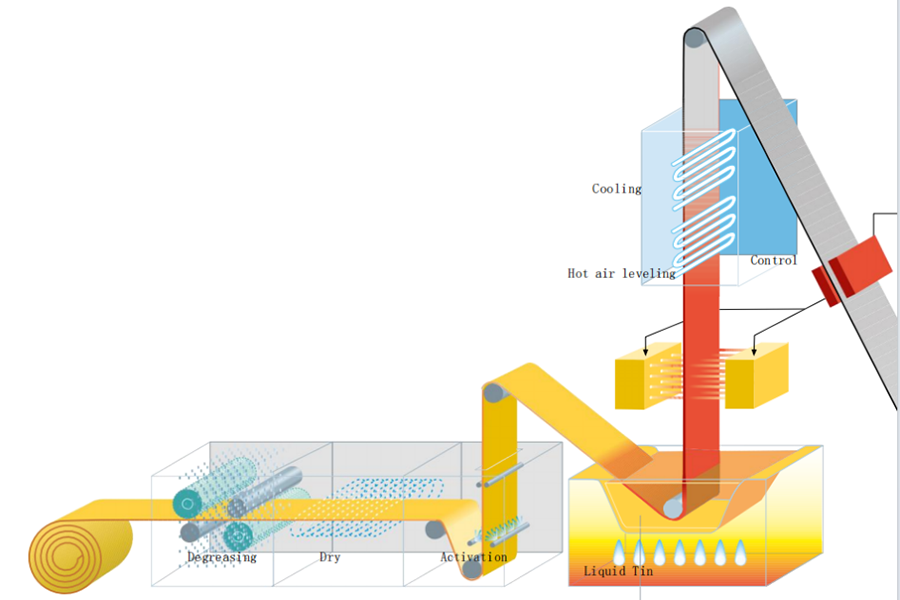

2) Kub-dip tinning: Nws yog rau raus dejtooj liabnyob rau hauv molten tin kua. Nyob rau hauv tej yam kub thiab lub sij hawm tej yam kev mob, cov tin kua reacts lub cev thiab tshuaj nrog rau qhov chaw ntawm lub tooj liab sawb los ua ib tug tin txheej rau ntawm qhov chaw ntawm tooj liab sawb.

II. Txheej yam ntxwv:

1) Txheej uniformity

A) Electroplating tinning: Cov txheej txheej txheej yog qhov zoo, thiab nws tuaj yeem tsim cov txheej txheem zoo nkauj thiab cov tinning rau ntawm qhov chaw.tooj liab. Tshwj xeeb tshaj yog rau cov tooj liab strips nrog cov duab nyuaj thiab qhov chaw tsis sib xws, nws tuaj yeem npog tau zoo, uas yog tsim rau daim ntawv thov scenarios nrog cov kev xav tau siab rau txheej txheej uniformity.

B) Kub-dip tinning: Cov txheej txheej tsis zoo yog qhov tsis zoo, thiab cov txheej tuab tsis sib xws yuav tshwm sim ntawm cov ces kaum thiab cov npoo ntawmtooj liab. Txawm li cas los xij, rau qee lub sijhawm uas qhov yuav tsum tau ua rau txheej txheej tsis yog tshwj xeeb nruj, qhov cuam tshuam me me.

2) Txheej thickness:

A) Electroplating tinning: Cov txheej tuab yog nyias nyias, feem ntau ntawm ob peb microns thiab kaum ntawm microns, thiab tuaj yeem tswj tau raws li qhov xav tau tshwj xeeb

B) Kub-dip tinning: Cov txheej tuab feem ntau yog tuab, feem ntau ntawm kaum ntawm microns thiab ntau pua microns, uas tuaj yeem muab kev tiv thaiv corrosion zoo dua thiab hnav tsis kam rautooj liab strips, tab sis nws yuav tsis haum rau qee daim ntawv thov nrog kev txwv nruj ntawm cov tuab.

III. Ntau lawm efficiency

1) Electroplating tin plating: Cov txheej txheem ntau lawm yog qhov nyuaj, xav tau ntau yam txheej txheem xws li kev kho ua ntej, electroplating, thiab tom qab kho. Kev ceev ntau lawm kuj qeeb thiab tsis haum rau cov khoom loj thiab kev ua haujlwm siab. Txawm li cas los xij, rau qee qhov me me-batch thiab customized ntau lawm xav tau, electroplating tin plating muaj qhov zoo adaptability.

2) Kub-dip tin plating: Cov txheej txheem ntau lawm kuj yooj yim. Cov txheej txheem tin plating tuaj yeem ua tiav los ntawm immersing lubtooj liabhauv tin kua. Kev ceev ntau lawm yog ceev thiab tuaj yeem ua tau raws li qhov xav tau ntawm cov khoom loj.

IV. Bonding zog:

1) Electroplating tin plating: Lub zog sib txuas ntawm cov txheej thiab covtooj liabsubstrate muaj zog. Qhov no yog vim hais tias cov tin ions tsim cov tshuaj tiv thaiv nrog cov atoms ntawm qhov chaw ntawm cov tooj liab nyob rau hauv qhov kev txiav txim ntawm hluav taws xob teb thaum lub sij hawm electroplating txheej txheem, ua rau lub txheej nyuaj poob tawm 5.

2) Kub-dip tin plating: Lub zog sib txuas kuj zoo, tab sis qee zaum, vim muaj cov tshuaj tiv thaiv nyuaj ntawm cov kua tin thiab qhov chawtooj liabThaum lub sij hawm kub-dip plating txheej txheem, qee qhov pores me me lossis qhov tsis xws luag yuav tshwm sim, cuam tshuam rau lub zog sib txuas. Txawm li cas los xij, tom qab kev kho kom zoo, lub zog sib txuas ntawm kub-dip tin plating tuaj yeem ua tau raws li qhov yuav tsum tau ua ntawm feem ntau cov ntawv thov.

V. Corrosion kuj:

1) Electroplating tinning: Vim yog txheej nyias, nws cov corrosion kuj tsis muaj zog. Txawm li cas los xij, yog tias cov txheej txheem electroplating raug tswj kom raug thiab tsim nyog tom qab kev kho mob, xws li passivation, yog ua tiav, qhov kev tiv thaiv corrosion ntawm cov khoom.tinned tooj liab stripkuj tuaj yeem txhim kho

2) Kub-dip tinning: Cov txheej yog tuab dua, uas tuaj yeem muab kev tiv thaiv corrosion zoo dua rau covtooj liab. Nyob rau hauv ib puag ncig hnyav, xws li av noo thiab corrosive gas ib puag ncig, corrosion kuj zoo dua ntawm kub-diptinned tooj liab stripyog pom tseeb 5.

VI. Nqi

1) Electroplating tinning: Cov cuab yeej siv peev yog me me, tab sis vim yog cov txheej txheem ntau lawm, nws siv hluav taws xob ntau dua thiab cov tshuaj reagents, thiab muaj cov kev xav tau siab rau qhov chaw tsim khoom thiab cov neeg ua haujlwm, yog li tus nqi tsim khoom kuj tseem siab.

2) Kub-dip tinning: Cov cuab yeej siv peev yog loj, thiab cov cua kub kub thiab lwm yam khoom siv yuav tsum tau tsim, tab sis cov txheej txheem ntau lawm yog qhov yooj yim thiab cov khoom siv raw siv me me, yog li cov nqi tsev yuav qis dua hauv cov khoom loj.

Xaiv ibtinned tooj liab striphaum rau koj daim ntawv thov scenario yuav tsum muaj kev xav txog ntau yam xws li hluav taws xob, khoom siv hluav taws xob, kev tiv thaiv corrosion, txheej txheem ntau lawm, nqi thiab kev tiv thaiv ib puag ncig. Raws li kev xav tau tshwj xeeb, ntsuas qhov zoo thiab qhov tsis zoo ntawm txhua yam thiab xaiv qhov tsim nyog tshaj plawstinned tooj liab striplos xyuas kom meej qhov kev ua tau zoo thiab zoo ntawm cov khoom.

Post lub sij hawm: Sep-18-2024